Air Leak Detection (ALD) & Stethoscope (ALS)

Optional Modules for KLIPPEL QC Framework

Features and Benefits

- Detect small air leaks and other defects

- Ambient noise immune (auto repeat)

- Simple setup

- End-of-line application (ALD - integrates in test sequence)

- Off-line diagnostics (ALS)

- Localize and auralize defects

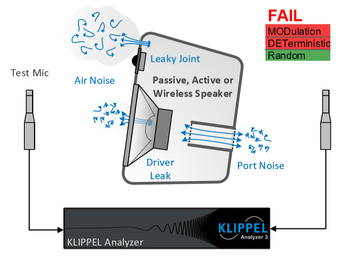

The Air Leak Detection (ALD) module applies special audio signal processing to isolate pulsating flow noise generated by air leakage in loudspeaker drivers and enclosures as well as ports and in orifices. Limits can be applied to the resulting absolute and relative distortion levels in order to qualify and quantify air leakage and many other defects (rubbing, buzzing, loose particles). This technology can be applied as an automatic end-of-line test which seamlessly integrates in the test sequence with single tone excitation or as part of the standard chirp measurement (Sound Pressure Task (SPL)).

Sharing the same processing kernel, the Air Leak Stethoscope (ALS) is a powerful off-line diagnostics tool to auralize and locate defects interactively.

Specification

Test Objects

- Low frequency drive units (woofer)

- Active and passive subwoofers units (closed, vented, band pass)

- Active or wireless mobile speakers (Bluetooth®)

- HiFi speakers and studio monitors

- Automobile audio systems

- Smart speakers

- Outdoor speakers

- Active mufflers

Requirements

Hardware

- KLIPPEL Analyzer 3 (KA3) or

- Production Analyzer (PA) or

- 3rd party audio interface (sound card)

License Dongle (US)

PC

Software

- QC Standard Software or

- QC Stand-alone Software or

- R&D Software 210 or higher

Accessories

- Microphones

- Power amplifier (optional for passive speakers)

- KA3 Amplifier Car

or

or - KA3 QC Card or

- 3rd party amplifier

- KA3 Amplifier Car

- Microphone multiplexer (optional)

- Headphones (optional)

Applications

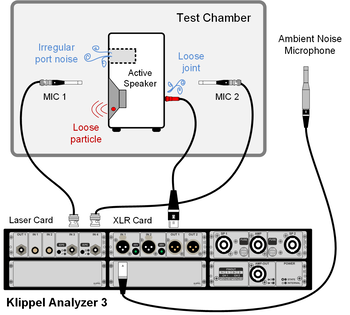

Comprehensive Active System Test

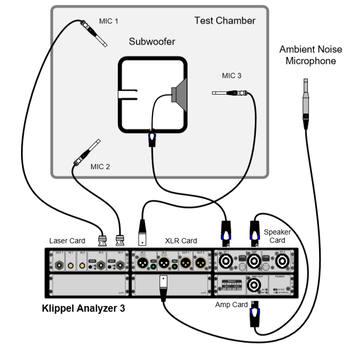

The picture shows a typical end-of-line test setup for active speaker systems such as a multimedia, Hi-Fi or portable speakers using KLIPPEL Analyzer 3 equipped with Laser Card and XLR Card. The main test microphone is located in the front for testing typical parameters such as frequency response, THD, Rub&Buzz distortion etc. using the SPL – Sound Pressure Task.

In order to detect loose joints, enclosure defects or irregular port noise, leakage testing can be simply integrated directly into the sweep test by activating the ALD option in the SPL Task without adding any extra test time. To make sure that rear defects and leakage problems are detected reliably too, another test microphone may be placed at the back of the speaker for an additional ALD test step. Up to four microphones can be used for a single shot test. During the complete test sequence, the ambient microphone outside the test chamber detects ambient noise disturbance reliably and triggers the auto-repeat mechanism for single test steps, if necessary.

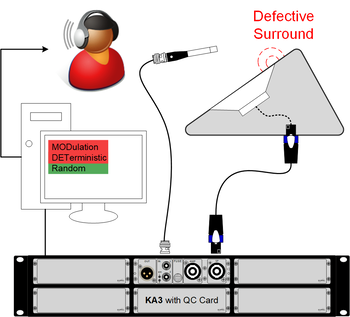

Inspection of Professional Speaker

The incoming goods inspection in a rental company for professional audio products (PA speakers, stage monitors…) is crucial to identify damage due to ageing or misuse. The ALS is a powerful tool to identify and localize such defects easily. Using noise insulated headphones the operator can test the equipment at critical playback levels with maximal sensitivity while protecting the ears.

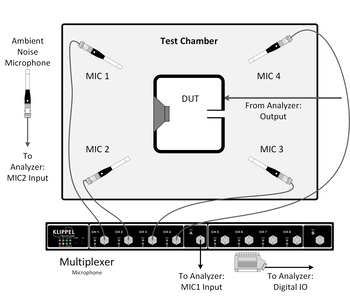

Microphone Array for Large Subwoofer

Detecting air leaks in large speaker systems with only one microphone suffers from acoustical shadowing of the high frequency leak noise. Locating multiple microphones around the device under test overcomes this problem and the complete surface can be covered for optimum sensitivity.

Sequential Test (Mic Multiplexer)

Using microphone arrays, the number of simultaneous input channels is usually limited by the analyzer such as the KLIPPEL Production Analyzer. In this example, four test microphones are switched by a multiplexer for sequential testing. An additional microphone outside of the test chamber monitors ambient noise in parallel. The test chamber ensures a low acoustical noise floor for maximal measurement sensitivity while the microphone detects impulsive disturbance reliably.

Simultaneous Test (KA3)

Using the KA3 hardware, a high number of input channels can be measured simultaneously using the signal data sharing feature. The QC software currently supports measuring with four microphones at the same time. In case ambient noise is measured (recommended), three other microphone channels are available that may be connected to the Laser Card (IEPE microphones) or the XLR Card (48 V microphones or IEPE using XLR-BNC adaptor). The stimulus signal is played back only once by the source ALD task, which is recording all input signals. The receiver tasks only processes the microphone signals recorded by the source tasks in order to generate the test results and verdicts for all microphones.

Driver Testing

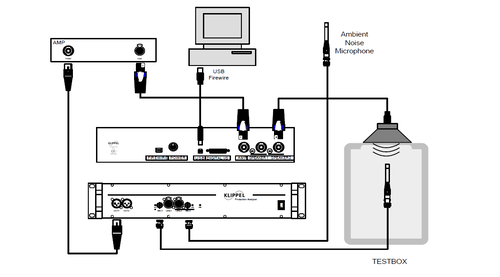

Gluing errors in drivers are likely to cause air leakage in the surround or the dust cap that may only be audible in the final application when the driver is mounted in a closed or vented enclosure. Such leaks may not be detected under free air conditions due to the lack of air pressure caused by the acoustical short-circuit at low frequencies. Measuring the driver in an adequately small test box provides the required in-box pressure at low frequencies to stimulate even very small driver leaks. Additionally, the test box offers ambient noise attenuation for maximal sensitivity in leak detection and driver testing.

Application Notes

Related Information

Other Modules of the QC System

• Spectrogram 3d Limits (3DL):

Powerful and intuitive defect (Rub & Buzz) analysis based on auditory time/frequency (spectrogram) analysis

• Meta-Hearing-Technology (MHT):

Defect detection beyond human hearing

• Spectrum Analysis (SAN):

FFT spectrum, frequency response, A-weighted SPL and distortion with/without noise generator or user-defined

stimulus for noise & vibration or audio system testing

Related Products

• QC Standard Software:

Full EOL-testing software for ultra-fast and complex measurements, incl. tasks (SPL, IMP, SAN, PP, IO),

QC Start and dB-Lab 210

General Features of the QC System

• Comprehensive Testing

• Fast as a Flash

• Sensitive Rub&Buzz Detection

• Production Noise Detection

Literature and Papers

• Measurement of Turbulent Air Noise Distortion in Loudspeaker Systems

Standards

International Electrotechnical Commission

IEC 60268-21

Patents

Germany: 102009033614; USA: 8,401,823B2; China: ZL201010228820.8