DC Displacement – Dynamic Offset the Voice Coil

Characteristics: | KLIPPEL R&D System | KLIPPEL QC System |

|---|---|---|

DC displacement versus frequency | DIS | DCX |

DC displacement versus amplitude | DIS | |

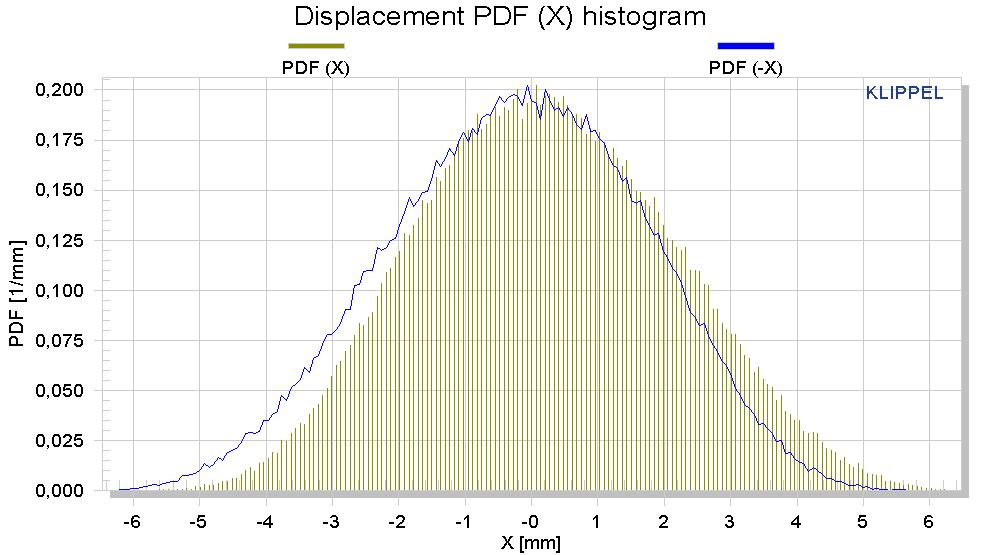

Asymmetrical probability function pdf | LSI3, PWT | |

| Peak-bottom value | DIS, TRF, LSI, PWT, SPM, LAA | MSC, DCX |

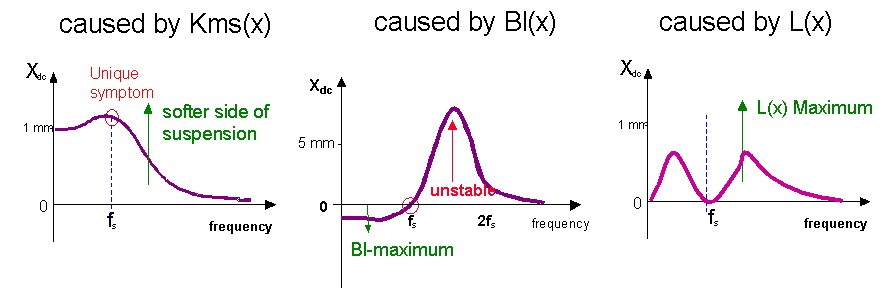

Asymmetries in the motor and suspension nonlinearities generate a dc component in the voice coil displacement which can be detected by a laser sensor. The sign of the dc component has a high diagnostic value because it is directly related with the shape of the nonlinearity. For example, an asymmetrical stiffness characteristic generates a dc component which always shifts the coil to the softer side of the suspension. An asymmetrical force factor characteristic may cause a significant dc component for excitation frequencies above resonance in the same order of magnitude as the fundamental. DC displacement generated by a poor suspension system may spoil the performance of an expensive motor structure because a dynamic voice coil offset produces audible intermodulation distortion.

The figure to the left illustrates the typical frequency of the dc displacement caused by an asymmetrical shape of nonlinear stiffness Kms(x), nonlinear force factor Bl(x) and nonlinear inductance L(x).

KLIPPEL R&D SYSTEM (development)

Module | Comment |

|---|---|

TRF reveals the dc component in the waveform of the displacement and in the Rub & Buzz analysis (instantaneous distortion 3D plot). | |

LSI3 predicts the dc displacement generated by a pink noise stimulus by using the nonlinear large signal model and the identified loudspeaker parameters. The predicted value can be compared to the value measured independently by using a laser sensor. | |

PWT provides similar features like the LSI but may be used to monitor the dc component of multiple devices under test using ordinary audio signals. | |

DIS module measures the steady-state response of the dc component versus frequency at different excitation levels. | |

| Live Audio Analyzer (LAA) | LAA measures the dynamic dc displacement versus time. Generated pink noise, or any given music signal may be used. In addition, by using linear modelling, irregular Rub & Buzz effects can be auralized. |

KLIPPEL QC SYSTEM (end-of-line testing)

Module | Comment |

|---|---|

|

MSC calculates the dc component using the large signal model and the identified nonlinear parameters in ultra short time (< 1s).It dispenses with a laser sensor. |

| Dynamic Excursion Check and Control (DCX) | The DCX Add-On to the SPL task analyzes the envelope of excursion and the dynamic offset of the voice coil using an excursion sensor. Limits can be applied and compression and non-linear (instable coil position) effects can be detected. A sine chirp stimulus is used. A KA3 hardware with DC coupled inputs is recommended. |

Templates of KLIPPEL products

Name of the Template | Application |

|---|---|

DIS Motor stability | Checking motor stability at frequency 1.5 fs (where Xdc is maximal) according Application Note AN 14 |

DIS X Fundamental, DC | Fundamental and DC component of displacement |

SIM X Fundamental, DC | Maximal displacement, dc displacement, compression using large signal parameters imported from LSI; Results are comparable with DIS X Fundamental, DC. |

SIM Motor Stability | Checking motor stability according Application Note AN 14; Simulated results are comparable with DIS Motor stability. |

Diagnost. MIDRANGE Sp1 | Comprehensive testing of midrange drivers with a resonance 30 Hz < fs < 200 Hz using standard current sensor 1 |

Diagnost. RUB&BUZZ Sp1 | Batch of Rub & Buzz tests with increased voltage (applied to high power devices) |

Diagnost. RUB & BUZZ Sp2 | Batch of Rub & Buzz tests with increased voltage (applied to low power devices) |

Diagnost. SUBWOOFER (Sp1) | Comprehensive testing of subwoofers with a resonance 10 Hz < fs < 70 Hz using standard current sensor 1 |

Diagnostics MICROSPEAKER Sp2 | Comprehensive testing of microspeakers with a resonance 100 Hz < fs < 2 kHz using sensitive current sensor 2 |

Diagnostics TWEETER (Sp2) | Comprehensive testing of tweeters with a resonance 100 Hz < fs < 2 kHz using sensitive current sensor 2 |

Diagnostics VENTED BOX SP1 | Comprehensive testing of vented box systems using standard current sensor 1 |

Diagnostics WOOFER (Sp1) | Comprehensive testing of subwoofers with a resonance 30 Hz < fs < 200 Hz using standard current sensor 1 |

Diagnostics WOOFER Sp1,2 | Comprehensive testing of subwoofers with a resonance 30 Hz < fs < 200 Hz using current sensor 1 and 2 |

Separate suspension | Separated stiffness of surround and spider according to Application Note AN 2 |

SPM Suspension Part | Nonlinear stiffness of spiders and smaller cones based on ONE-SIGNAL Method |

LSI Tweeter Nonlin. Para Sp2 | Tweeters with fs > 400 Hz at sensitive current sensor 2 |

LSI Headphone Nonlin. P. Sp2 | Nonlinear parameters of headphones with fs < 300 Hz at sensitive current sensor 2 |

LSI Woofer Nonl. P. Sp1 | Nonlinear parameters of woofers with fs < 300 Hz at standard current sensor 1 |

LSI Woofer Nonl.+Therm. Sp1 | Nonlinear and thermal parameters of woofers with fs < 300 Hz at standard current sensor Sp1 |

LSI Woofer+Box Nonl. P Sp1 | Nonlinear parameters of woofers operated in free air, sealed or vented enclosure with a resonance frequency fs < 300 Hz at standard current sensor Sp1 |

LSI Microspeaker Nonl. P. Sp2 | Nonlinear parameters of microspeakers with fs > 300 Hz at sensitive current sensor 2 |

TRF Crest Harmonics (x,f) | Crest factor harmonic distortion versus displacement to find Rub & Buzz and other loudspeaker defects |

TRF Peak harmonics, time domain | Peak value of higher-order harmonics in time domain for Rub & Buzz analysis |

TRF rubb+buzz w/o Golden Unit | Rub & Buzz detection without "Golden Unit" according Application Note AN 22 |

TRF rubb+buzz with Golden Unit | Rub & Buzz detection with "Golden Unit" according Application Note AN 23 |

DIS Compliance Asymmetry AN 15 | Checking for asymmetries caused by compliance according Application Note AN 15 |

SIM closed box analysis | Maximal displacement, dc displacement, compression, SPL, distortion using large signal parameters imported from LSI BOX |

SIM Compression Out(In) | Output amplitude versus input amplitude at four frequencies using large signal parameters imported from LSI; Simulated results are comparable with DIS Compression Out(In). |

SIM vented box analysis | Maximal displacement, dc displacement, compression, SPL, harmonic distortion using large signal parameters imported from LSI BOX |

Application Notes

AN 1 Optimal Voice Coil Rest Position

AN 2 Separating Spider and Surround

AN 3 Adjusting the Mechanical Suspension

AN 13 Dynamic Generation of DC Displacement

AN 14 Motor Stability

AN 15 Checking for Compliance Asymmetry

AN 21 Reduce Distortion by Shifting Voice Coil

AN 24 Measuring Telecommunication Drivers

AN 26 Nonlinear Stiffness of Suspension Parts

Standards

Audio Engineering Society

AES2 Recommended practice Specification of Loudspeaker Components Used in Professional Audio and Sound Reinforcement

International Electrotechnical Commission

IEC 60268-5 Sound System Equipment, Part 5: Loudspeakers

Other Related Tests

Typical Test Objects

Papers and Preprints

W. Klippel, Tutorial “Loudspeaker Nonlinearities - Causes, Parameters, Symptoms,” J. of Audio Eng. Soc. 54, No. 10, pp. 907-939 (2006 Oct.).

W. Klippel, “Assessment of Voice-Coil Peak Displacement Xmax,” J. of Audio Eng. Soc. 51, Heft 5, pp. 307 - 323 (2003 May).

W. Klippel, “Nonlinear Large-Signal Behavior of Electrodynamic Loudspeakers at Low Frequencies,” J. of Audio Eng. Soc., Volume 40, pp. 483-496 (1992).

W. Klippel, “Prediction of Speaker Performance at High Amplitudes,” presented at 111th Convention of the Audio Eng. Soc., 2001 September 21–24, New York, NY, USA.