KLIPPEL Endurance Test (KET)

Features and Benefits

- Dedicated solution for long-term, power and accelerated life tests

- Testing passive audio systems or any transducer

(woofer, micro-speaker, headphones) - Monitors up to 32 DUTs simultaneously

- Reveals the destruction process in detail

- Stimulus shaping, cycling and stepping

- User-defined failure limits

- Monitors data of user-defined, external sensors (e.g., temperature & humidity)

- Control peripheral devices (e.g., heating chambers)

KLIPPEL Endurance Test (KET) solution provides a simple-to-use, cost-efficient soft- and hardware solution to run multi-channel long-term, power, and accelerated life tests for typical quality assurance (QA) applications such as validation checks or type approvals. Test signals can be defined flexibly using predefined stimuli as well as arbitrary wave files. Level stepping and cycling are available for any signals. Each DUT is monitored individually. Failures can be automatically detected by checking against user-defined limits. Open and short circuits are detected by general limits; thus, a destroyed device is detected immediately. A “Death Report” reveals details of monitored states at the highest available rate for a limited time just before the failure was detected.

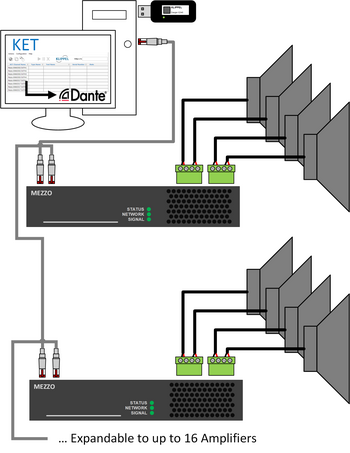

32 DUTs can be measured using one PC. Even a higher channel number up to max. 64 channels, depending on PC performance and Dante® Interfaces, is possible (see references). Each DUT test can be individually started, muted and terminated. Each DUT can have its own test signal and configuration. The current test status of all DUTs can be visualized in a dashboard. Status information can be easily accessed via any browser device in the network. Dante® technology is used for streaming data via a (wired) network connection.

KET follows our market-leading long-term testing solution Power Monitor 8 (PM8) with the Power Testing (PWT) module. Note that PM8 and PWT are deprecated. The following feature comparison compares our long-term test solutions and gives a general feature overview.

Feature Comparison

| Feature | KLIPPEL Endurance Test (KET) | Power Test (PWT) - Deprecated |

|---|---|---|

| Max. Num DUTs | 32 (64) |

8 (using Power Monitor 8) 2 (using Distortion Analyzer) |

| Signals |

Voltage / Current No Displacement |

Voltage / Current (PM8) + Displacement (1 DUT only, DA2) |

| Sample Rate | Up to 192 kHz (depends on Amp) | 48 kHz |

| Sources | Internal (predefined stimuli) | Internal (predefined stimuli) |

| External audio signal | External audio signal | |

|

Any wave file (PC playback), length restricted |

Bypass Mode (Analog input) (Monitoring any amplifier output) | |

| Any stimulus generated by MTON | - | |

| Stimuli (internal) |

• Pink Noise • White Noise • IEC / EIA • Multi-tone • Two-tone • Chirp |

• Pink Noise • White Noise • IEC / EIA • Two-tone • Chirp |

| Voltage Control |

Of amplifier output voltage for any internal stimuli. For Wave-Files: • dBFS-mode • Fixed rms mode • Rms Normalized |

For internal and external sources. Not available for Bypass mode |

| Voltage Stepping | Linear, Exponential, User defined | Linear, Exponential |

| Intermittent Excitation | Yes | Yes |

| Stimulus Crest Factor | User-defined (6 – 18 dB) | User-defined (6 – 18 dB) |

| Filter for stimulus | 6/12/24/48/∞ dB | 6/12 dB |

| Sampling Interval | 1s |

1s for 1 DUT (Minimum) 8s for 8 DUTs (Minimum) |

| States | U / I / P / R / T | U / I / P / R / T / X (1 channel only) |

Requirements

- PC

- Power Amplifiers (Powersoft Mezzo)

- Network / Audio Distribution (Dante®)

- License Dongle (USB)

Software

- dB-Lab

- Dante® Interface

- KET Dashboard

Accessories

Literatur

- W. Klippel, “Nonlinear Modeling of the Heat Transfer in Loudspeakers,” J. of Audio Eng. Soc. 52, Volume 1, 2004 January.

- Henricksen, “Heat Transfer Mechanisms in Loudspeakers: Analysis, Measurement, and Design,” J. of Audio Eng. Soc., Volume 35, No. 10, 1987 October.

Demo Videos

Introduction Video

The video shows an overview of the new power and endurance test solution made by KLIPPEL in general and in particular an introduction to the KET structure and benefits.

Video: KET Introduction

With loading this video, you agree that your data will be transferred to YouTube and that you have read our data protection policy.

Getting Started Video

The video shows an introduction to how to prepare the hardware and install the required software (e.g., Dante Virtual Sound Card, Dante Controller, dB-Lab 212, KET-setup).

Video: KET Getting Started

With loading this video, you agree that your data will be transferred to YouTube and that you have read our data protection policy.

Examples

Continuous Testing

The simplest test is continuous playback of test stimuli for a defined duration. Monitoring power, temperature, voltage, and current reveals steady state performance for given environmental conditions. Thermal equilibrium may take hours to settle, especially for larger woofers. For mass production, regular statistical investigation of the fault rate may be required. KET eases this process considerably by using multi-channel tests and template-based setups applied to a given number of DUTs. » KET Example Data

Voltage and Current

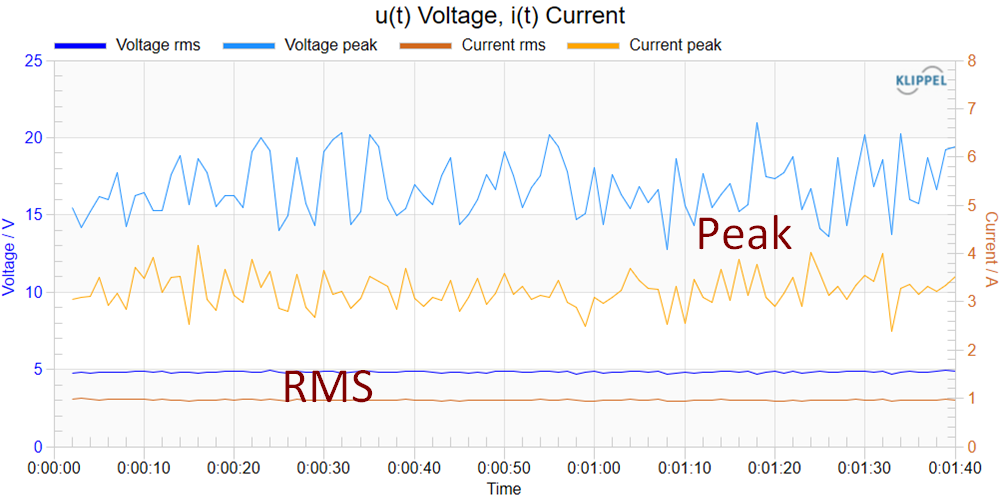

Power amplifiers used for KET are voltage driven, thus, the actual voltage at amplifier output can be monitored and compared with the specified level in setup. Current and voltage are provided as rms and as peak values. Potential clipping or power compression can be checked in the chart Device Compression / Limiter.

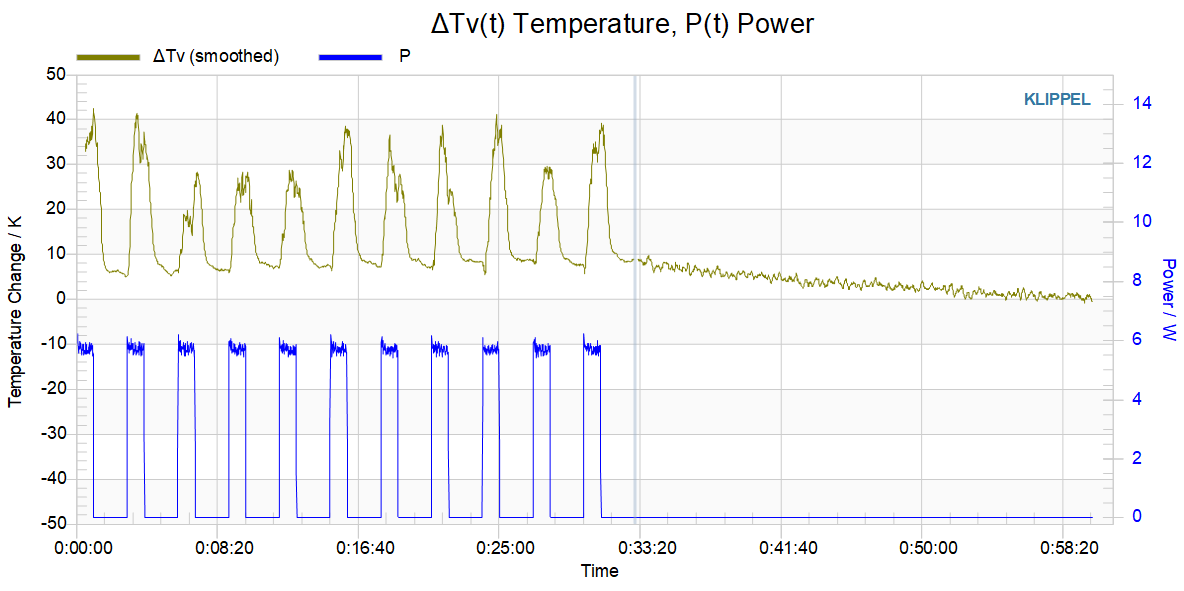

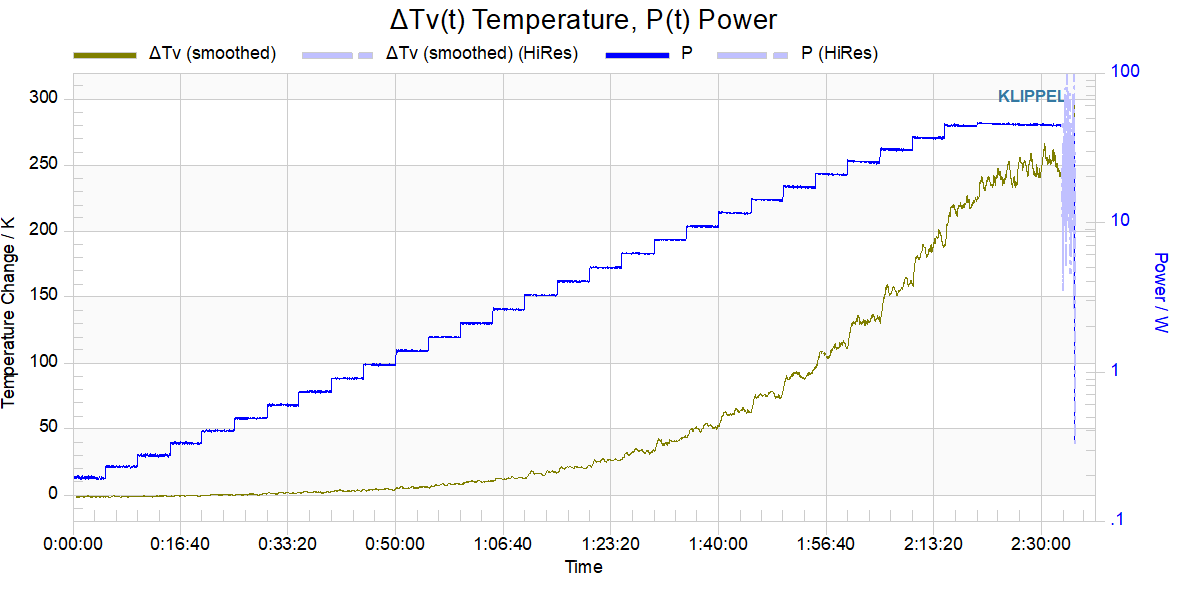

Temperature, Input Power

The voice coil temperature is closely related to the real input power supplied to the transducer. Note the dual Y axis in the chart. Both state variables plotted versus measurement time give important information for defining admissible maximal input power. For a continuous playback test the steady state temperature for the given level can be assessed.

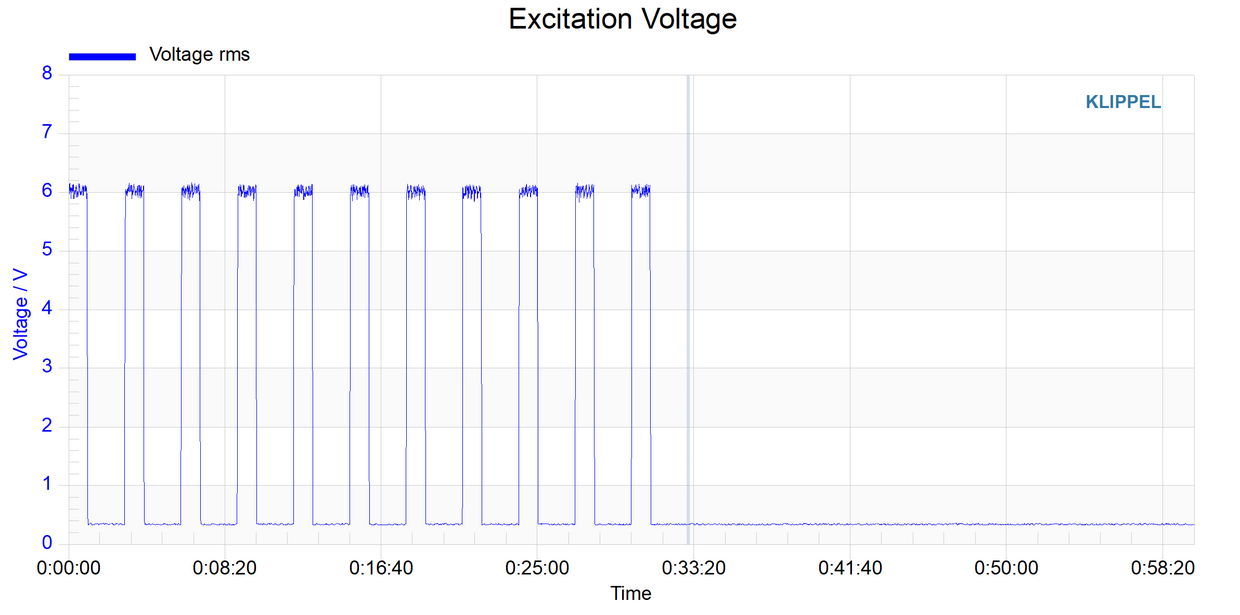

Accelerated Stress Test

Special profiles of excitation level and/or environmental conditions are used to accelerate the life cycle of a transducer. Fast changes in conditions stress the DUT and simulate a typical load scenario of product life in a much shorter time. One typical test (which is also used to determine the long-term maximum sound pressure level according to IEC 60268-21 cl. 18.4) is alternating high level with resting (cooling down). KET provides many options to alternate or step up/down the level for any kind of stimulus. Templates provide predefined setups according to international standards for easy setup and use. » KET Example Data

Destructive Testing

Most devices undergo thorough testing within their specified limits, but it's important to also test their maximum capabilities. Klippel Endurance Testing (KET) is a useful tool for determining the highest allowable power and coil temperature. The test automatically stops if the device is damaged or exceeds individual power, current, or temperature limits. The final 100 seconds of the test provide detailed information about the device's behavior during this crucial phase. » KET Example Data

Temperature, Input Power

In this example, the test level is increased every 5 minutes by 1 dB steps up to a maximum test level of 25V / 45 W. Note the logarithmic y-axis for power. The device under test, a small automotive woofer that is specified with a 12V max rms level, withstands more than twice that specified level for about 5 minutes. The coil temperature at the breakdown was measured at about 250°C. Note, that the coil temperature is averaged over the coil, usually the outer parts of the coil are less cooled and may be considerably hotter than the inner parts.

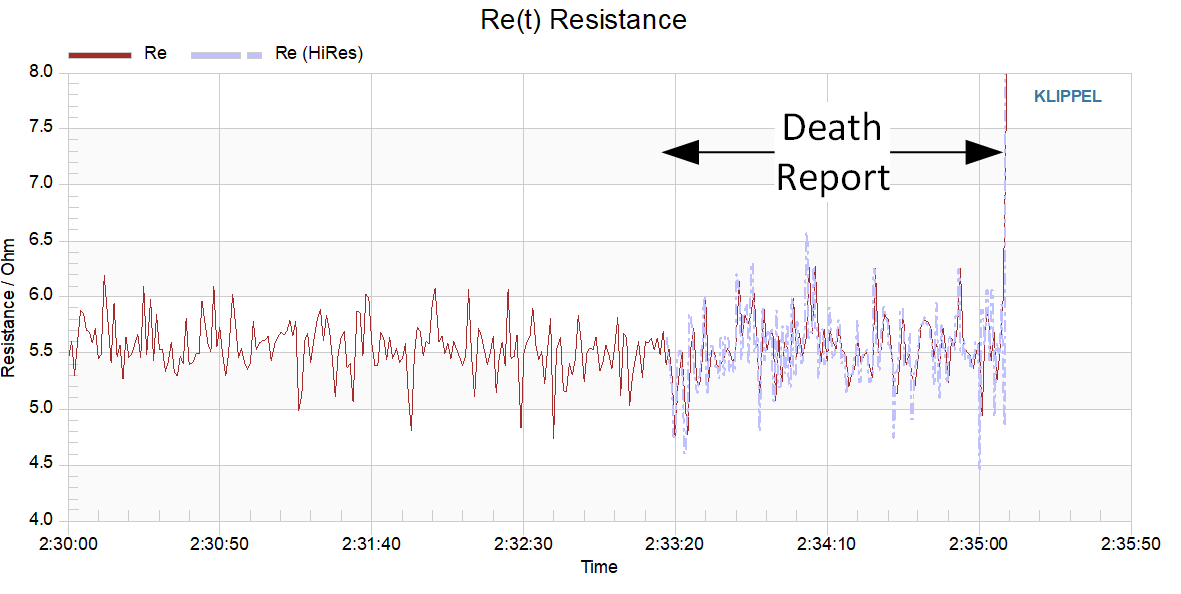

Death Report

A death report provides high-resolution data just before a detected failure. A ring buffer of 100 seconds length stores results at the highest available rate, here about 200ms. This may reveal the root causes for a malfunction. In this example, the coil suddenly broke and the resistance jumped up quickly causing an open circuit failure.

Thermal Stress Test

Thermal stress tests are part of environmental stress tests that can be performed or even combined by applying excessive heat, humidity, water, salt, or other aggressive chemicals to devices under test (DUT). Such tests prove the resistance of DUTs to tough environmental conditions that might appear in the final application. They are also part of accelerated live tests, which reveal aging and fatigue problems in a much shorter time than the actual product lifetime. » KET Example Data

Temperature Profile Test

A temperature sensor (red) measures the environmental temperature in a climate chamber while the voice coil temperature is plotted in brown. The test consists of 4 phases at room temperature, a heating phase, a freezing phase, and a resting phase, about 90 minutes each. Here the environmental heat and cold add additional thermal stress to the voice coil and the DUT, resulting in high coil temperature even at moderate excitation levels.

In this example, the external temperature sensor is automatically queried using an open API for any kind of sensor and included in result charts. Thus, other conditions using almost any digital sensor can be monitored and integrated into KET. Moreover, a software interface is available to control climate chambers or other instruments of torture for DUTs for automatic long-term tests with specific test profiles. As always after endurance testing, the compliance with expected behaviour shall be verified. Note that room temperature offset (20°C) was added to the measured coil temperature increase allowing comparison on an absolute scale.