Balanced Armature Check (BAC)

Optional Module for the KLIPPEL QC Framework

Features and Benefits

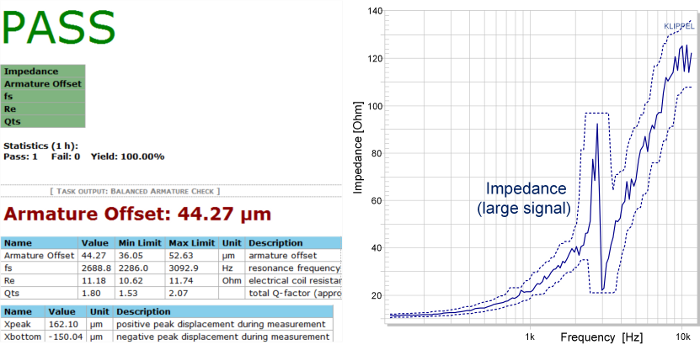

- Armature offset in μm

- Patented large signal parameter identification

- High speed test: 0.5 - 2 s

- Linear parameters: Re, fs, Qts, Le

- Peak excursion of armature (without laser)

- Immune to production noise

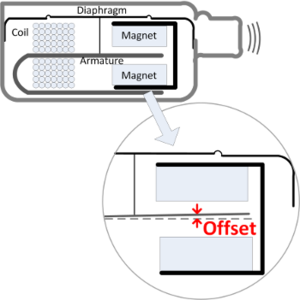

The performance of balanced armature transducers depends on the rest position of the armature, which should be properly centered in the magnetic gap. An offset generates excessive nonlinear distortion and reduces the peak excursion and acoustical output. Measuring the armature offset of the final transducer is hardly possible with mechanical or optical sensors.

The Balanced Armature Check is a unique measurement tool dedicated to testing electro-magnetic transducers on the production line. The armature offset in μm and effective linear parameters are determined from a purely electrical, high-speed measurement. This gives valuable diagnostics information to minimize the rejection rate.

Specification

Requirements

Hardware

License Dongle (USB)

PC

Software

- QC Standard Software or

- QC Stand-alone Software or

- R&D Software 210 or higher

Accessories

KA3 QC Card or

3rd party amplifier

Demo Video

Related Information

Other Modules of the QC System

• Motor + Suspension Check (MSC):

Fast measurement of voice coil offset and suspension asymmetry

General Features of the QC System

• Comprehensive Testing

• Fast as a Flash

Standards

Patents

Germany: 10 2013012811; USA: US9,326,066B2; China: 2014 103 769646; Korean: 10-1647315