Typical Applications of KLIPPEL QC SYSTEM

Content

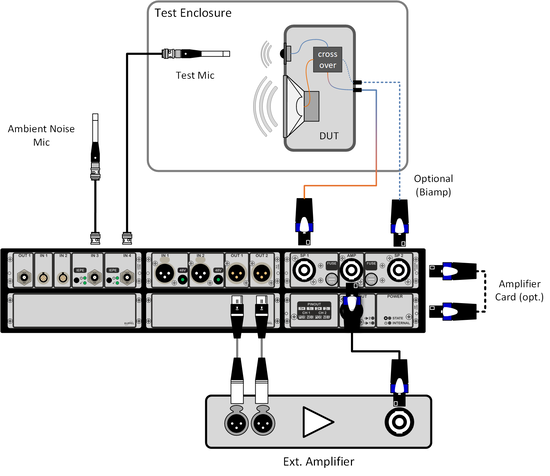

Woofer End-of-Line Test

The basic setup for testing single drivers comprises the KLIPPEL Analyzer 3 with QC or (A)LSX configuration, an external power amplifier (opt.), microphone(s) and a computer running KLIPPEL QC software. The KA3 Amplifier Card and QC Card provide an integrated power amplifier. An external amplifier is only required for high voltage or power requirements. In most cases the DUT and the near field microphone is mounted into a test box providing some basic ambient noise attenuation. However, complete noise immunity can only be achieved using Production Noise Detection or Production Noise Immunity (PNI) based on an external ambient noise microphone.

Related Information

QC System - Interactive Demo Tour

AN 45 - Optimal QC Setup for Fixed Time

AN 46 - Test Enclosure for QC

AN 48 - Yield Statistics

Passive Speaker

The schematic shows a typical EoL test setup for passive speaker systems that consist of one or multiple transducers and crossover networks mounted in a sealed or vented speaker enclosure such as subwoofers, multi-way HiFi speakers or passive PA speakers. The KA3 Amplifier Card provides two individual amplifier channels and is suitable for driving most DUT types, but an external power amplifier can be connected to the analyzer for higher power requirements.

The test microphone is located on the tweeter’s main axis and measures fundamental frequency response, sensitivity, distortion, rub&buzz and air leakage noise and other sound pressure-based parameters. A second microphone outside the test enclosure reliably detects corrupted measurements.

The terminal voltage and input current are measured simultaneously or in a consecutive step and yield the DUT impedance magnitude of the full system including crossover. In case the tested device provides dedicated inputs (e.g. bi-amp terminals in a two-way system), the drivers can be tested separately using the two available speaker channels of the KA3. This allows to test Thiele/Small parameters including box parameters like box resonance and Q factor for vented enclosures. Adding a KLIPPEL multiplexer, up to eight channels can be switched and tested individually.

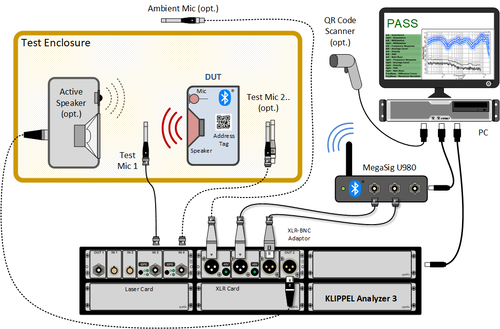

Active Speaker

The picture shows a typical end-of-line test setup for active speaker systems such as a multimedia, Hi-Fi or portable speakers using KLIPPEL Analyzer 3 equipped with Laser Card and XLR Card. The main test microphone is located in the front for testing typical parameters such as frequency response, THD, Rub&Buzz distortion etc. using SPL – Sound Pressure Task.

In order to detect loose joints, enclosure defects or irregular port noise, leakage testing can be integrated simply, directly into the sweep test by activating the ALD option in the SPL Task without adding any extra test time. To make sure that also rear defects and leakage problems are detected reliably, another test microphone may be placed at the back of the speaker for an additional ALD test step. Up to four microphones can be used for a single shot test. During the complete test sequence, the ambient microphone outside the test chamber detects ambient noise disturbance reliably and triggers the auto-repeat mechanism for single test steps, if necessary.

Related Information

Demo Video - Active 2.1 System Testing

AN 64 - Housing Ground Check

Bluetooth Speaker

For test automation of Bluetooth-enabled speakers and headphones, the EXD enhances any QC test sequence with Bluetooth pairing and audio control capabilities through MegaSig U980 analog Bluetooth interface.

At the beginning of the test sequence, the EXD triggers scanning of the DUT address for pairing or the next available device is paired. The A2DP audio profile is activated to test the speaker output using a test microphone connected to the KA3. In the next step, the HFP (hands-free) profile is activated for testing the DUT’s microphone response. The reference speaker is connected to the output of the analyzer to play back the test signal.

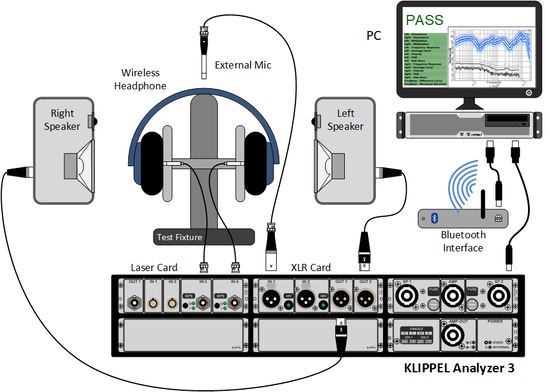

Headphone Testing

The quality of earphones, headphones or headsets depends on many factors. In R&D, important design parameters are specified by several standards. Measurements with ear simulators provide defined load conditions and specied frequency responses. However, performing such tests can be a challenging and time-consuming task that requires experience and careful handling in order to obtain meaningful and reproducible results.

In quality control, other requirements like simple handling, speed, stability, robustness against ambient noise and reproducibility are much more important in order to pursue the ultimate goal of distinguishing good from bad units reliably. The most important test parameters are the frequency response and the matching between left and right channel. Furthermore, excessive harmonic distortion shall be reliably detected as well as any disturbing rattling and buzzing noises, even if operated at high level. Additionally, the functionality of signal processing features like ANC (active noise control) need a quick verification.

Application Note 73 specifically focuses on the aspects of QC testing for testing passive, digital (USB) and wireless (Bluetooth) headphones and headsets using dedicated headphone test stands by GRAS. The stated information can be transferred to other devices like earphones or hearing aids.

Related Information

AN 73 QC Headphone Testing

Demo Video - Headphone Testing

Subwoofer Air Leak Test

Detecting air leaks in large speaker systems with only one microphone suffers from acoustical occlusion of the high frequency leak noise. Locating multiple microphones around the device under test overcomes this problem and the complete surface can be covered for optimum sensitivity.

Sequential Test (Mic Multiplexer)

Using microphone arrays, the number of simultaneous input channels is usually limited by the analyzer such as the KLIPPEL Production Analyzer. In this example, four test microphones are switched by a multiplexer for sequential testing. An additional microphone outside of the test chamber monitors ambient noise in parallel. The test chamber ensures a low acoustical noise floor for maximal measurement sensitivity while the microphone detects impulsive disturbance reliably.

Simultaneous Test (KA3)

Using the KA3 hardware, a high number of input channels can be measured simultaneously using signal data sharing feature. The QC software currently supports measuring with four acoustical microphones at the same time. In case ambient noise is measured (recommended), three other microphone channels are available that may be connected to the Laser Card (IEPE microphones) or the XLR Card (48V microphones or IEPE using XLR-BNC adaptor). The stimulus signal is played back only once by the source ALD task which is recording all input signals. The receiver tasks only process the microphone signals recorded by the source tasks in order to generate the test results and verdicts for all microphones.

Smart Speaker

So-called smart speakers and other voice-controlled devices are highly integrated audio system that typically do not provide any wired audio input or output for testing the speaker output or integrated MEMS microphone responses with defined test signals. If the device is Bluetooth enabled, a wireless link can be used for closed-loop test scenario (see Bluetooth Speaker).

However, this is often not available and not suitable for critical microphone testing, the QC software provides smart methods to overcome this dilemma with wave-file bases open loop testing. Using the SYN add-on, any test stimulus sequence can be exported to wave files and transferred to the DUT e.g. via a cloud service. Playback can be triggered using a recorded voice command played by a reference speaker. The unique SYN trigger signal takes care of synchronizing the analysis of the response recorded by the test mic.

The device’s microphones are tested the other way round. The KLIPPEL Analyzer (or sound card) plays back the test signal via the reference speaker while the DUT is recording the internal mic responses to an audio file. These files are transferred to the test PC and imported to the QC software seamlessly for analysis.

Related Information

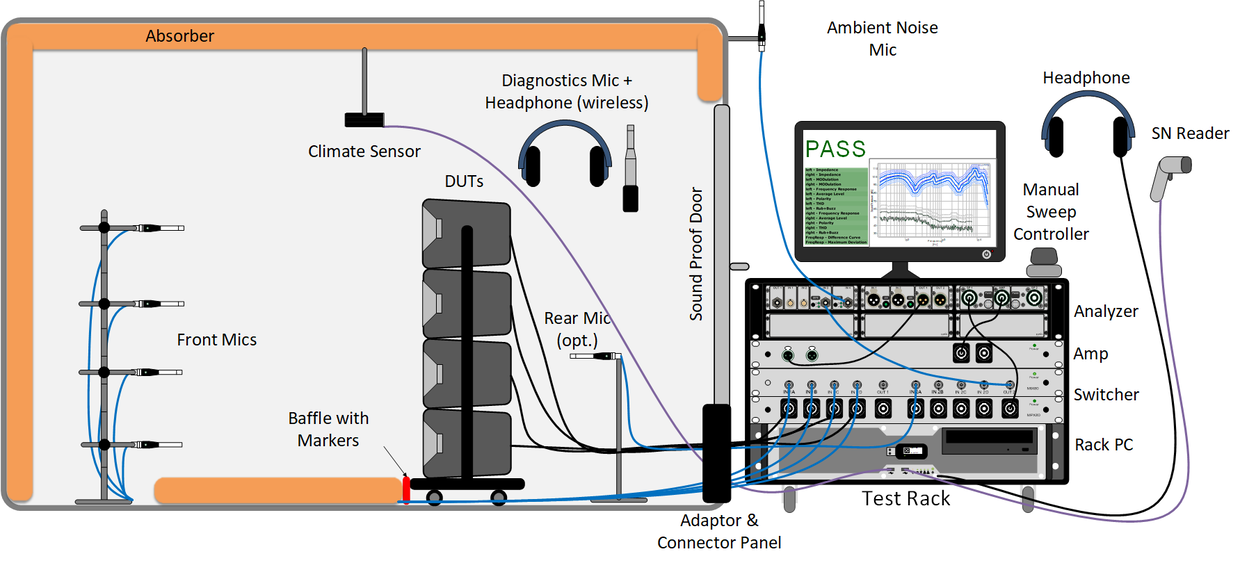

Quality Control of Sound Reinforcement Equipment

In commercial, public events the audience expects nothing but a flawless performance of the involved audio equipment. Especially in concerts, defects in the most stressed component of the audio system - the loudspeakers - can impair the experience drastically. For most rental houses the required effort and know-how are limiting factors for implementing a critical and objective functionality check for a large number of loudspeaker units. Therefore, simple listening test are common, which are inaccurate, highly subjective, stressful for the operator and can even damage the hearing, while critical sound pressure levels cannot be used at all. Defects may go unnoticed resulting in failure in the worst moment, in front of the audience, where no solution is available.

KLIPPEL QC is the right tool to overcome these problems with straight-forward, objective quality control. Single loudspeakers and even complete line array stacks can be tested in one fast sequence that can be easily operated for reliable defect detection even beyond the flaws of human hearing.

A dedicated App Note 79a for the QC System provides clear directions for setting up and operating such a test station. The main step-by-step guide addresses a full featured setup that includes a test box providing controlled conditions and insulation of peak SPL contamination as well as ambient noise disturbance.

The suggested strategies assure that problems are detected as early as possible and that your equipment leaves the door completely functional. Carrying out the tests does not require trained specialists and can be done by any staff member. Following this guideline helps you maintaining a professional quality level of your audio systems providing a major advantage over your competition and a base for long term trust between you and your clients. The guidelines given are also highly suitable for manufacturers loudspeakers for sound reinforcement applications. An alternative, mobile and scaled-down testing approach is introduced in App Note 79b. This app note relies onsmart audio-over-IP amplifiers together with QC Stand-alone Software as test frontend.

Related Information

AN79a QC of Sound Reinforcement Equipment

AN79b Efficient, Mobile Quality Assurance of PA Speaker

Accessories

AES Workshop Presentation (2020)

Efficient, Mobile Quality Assurance of PA Speakers with Audio-over-IP Amplifiers

The scenario introduced in application Quality Control of Sound Reinforcement Equipment refers to a full-featured QC testing approach that provides optimum performance for manufacturers of PA speaker or big rental houses.

However, this concept based on a dedicated soundproof chamber is not suitable in many cases. Therefore, a scaled-down, price-efficient approach for smaller companies, secondary test sites and mobile test setups is suggested in Application Note AN79b. Together with Tech Note TN17 - Setting up Dante & Powersoft Mezzo for QC Stand-alone, this concept relies on a minimal set of hardware components using a Dante® compatible audio-over-IP amplifier with integrated voltage and current sensors as the main test frontend operated with QC Stand-alone Software version. It also suggests a simple and effective test strategy that relies on a small set of single value, relative metrics that can be tested against universal pass/fail and grade limits.

The main step-by-step guide addresses a standard setup that does not incorporate a test box or separate measurement-room. However, a semi-open test box can be added to provide more controlled and reproducible conditions and a limited amount of sound attenuation.

Related Information

AN79a Quality Control of Sound Reinforcement Equipment

AN79b Efficient, Mobile Quality Assurance of PA Speaker

TN17 Setting up Dante & Powersoft Mezzo for QC Stand-alone Software

Accessories

AES Workshop Presentation (2020)

Short Demo - Efficient QA of Professional Speakers

With loading this video, you agree that your data will be transferred to YouTube and that you have read our data protection policy.

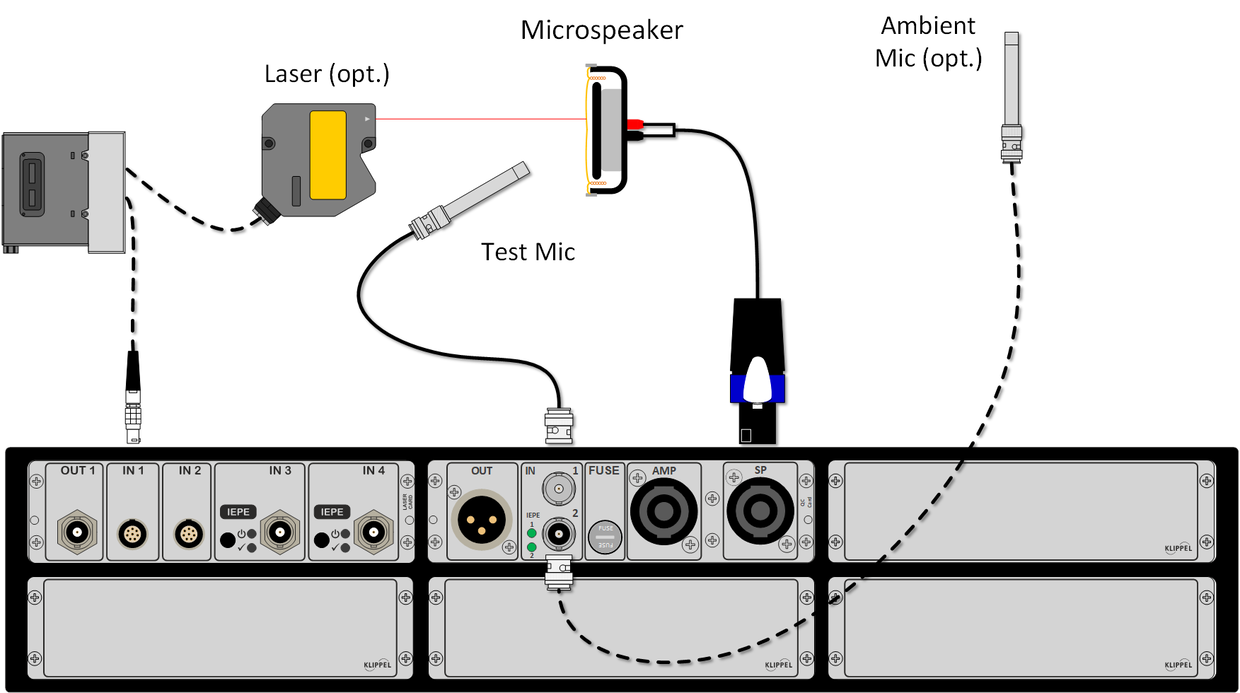

Microspeaker EoL Test

Micro- and miniature speakers as used in smartphones, headphones and other small audio devices are expected to deliver reasonable audio quality and max SPL despite of the small size and often low price. Mostly applied to reproduce speech, music and other broad band signals, these devices are prone to rocking, irregular vibration and mechanical asymmetries caused by production tolerances that may result in hard limiting (impulsive distortion) or dynamic DC shifts that further decrease the usable working range.

For this reason, a fast and critical EoL test is required to ensure consistent quality and provide the means for efficient process control ensuring high yield rate. The QC Card of the KLIPPEL Analyzer 3 is the optimal choice for microspeaker EoL testing providing a built-in DC coupled power amplifier, voltage and current sensing as well as two microphone inputs. Using QC standard software, frequency response, harmonic and impulsive distortion as well as T/S parameters can be tested within fractions of seconds. This is enhanced with full noise immunity adding PNI. Suspension asymmetries and voice coil rest position are tested by the unique Motor+Suspension Check (MSC) add-on, only based on electrical large signal measurement. Adding a KA3 Laser Card and a displacement laser sensor provides further powerful capabilities, such as peak and DC displacement testing (DCX) and full mechanical T/S parameter testing including Bl(0) and Mms (TSX) without adding extra test time.

Related Information

Demo Video -Micro Speaker Testing

Microphone Testing

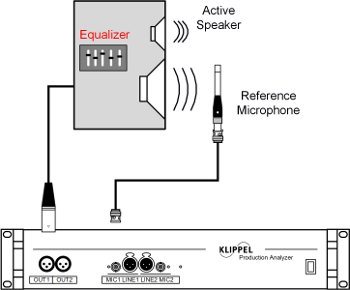

Different approaches are available for testing quality of microphones such as vocal and measurement microphones or built-in microphones in headsets or smart devices. Using a reference sound source , a controlled test environment (test enclosure) and a reference microphone, the DUT’s response can be tested relative to the reference mic (difference) using the insertion method. Alternatively, the sound source can be calibrated in order to achieve a defined frequency response at the test position using the EQA.

As an alternative to a test chamber, a small acoustic coupler may be used for suitable microphones using the same test strategy but allowing higher sound pressure levels. In addition to the fundamental frequency response, the harmonic and impulsive distortion can be are tested against limits to derive a PASS/FAIL verdict.

Spider Test (LST Lite)

A standard application of the LST Lite module is spider testing. For this application, the resonance frequency f0, the Q-factor and the effective stiffness k0 are measured.

Round spiders can be attached to the measurement bench using a subset of the modular ring set (optional). The cone for inner clamping is selected by the neck diameter of the spider. For this application, sound pressure measurement is optional but recommended for best accuracy (resonator parameter fitting). Once the measurement bench is adjusted and the software properties are set, large batches of spiders can be tested with a very short cycle time. The DUTs are only clamped by the weight of the mounting cone by gravity to minimize mounting time. For very soft suspension parts, an additional upper clamping ring may be used for additional support.

Passive Radiator Test (LST Pro)

For testing passive radiators, the LST Pro is recommended because both mass and stiffness deviation may vary in production. Mass deviation and stiffness deviation are calculated based on a physical model and defined relative to a defined reference unit (“Golden Unit”). This unit may be selected according to R&D specifications or automatic golden unit selection based on a batch of reference units. All subsequently measured devices are related to the reference unit. If the reference moving mass is known (e.g. from (M)SPM using added mass method), the parameter deviation can be monitored in absolute values or percent. If the passive radiator is not round, a custom platform may be mounted on top of the LST Bench. The outer frame must be fixed for reproducible conditions (e.g. using clampers).

In case the ambient conditions (temperature/humidity) have changed over time, the limits may be calibrated using the golden unit. It should be kept under the same ambient conditions close to the test station.

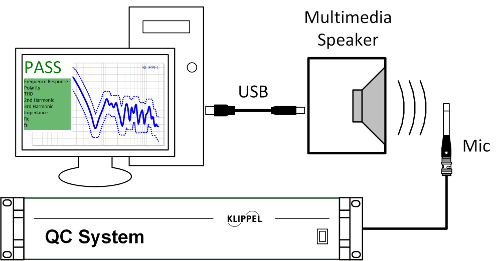

USB Multimedia Speaker

If the test signal is played back through USB audio, the delay is usually unknown. However, proper synchronization can be established dynamically through the acoustical measurement channel. Subsequent measurements use the detected delay for sample-correct analysis.

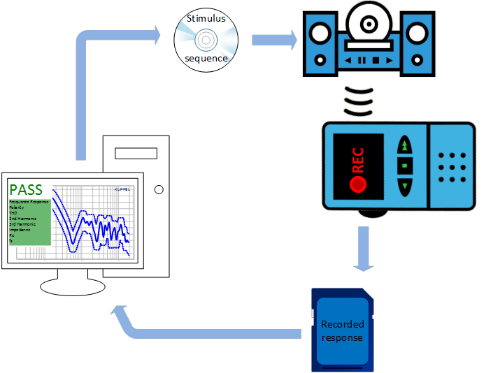

Automobile Audio System

If the device under test (in this example an automobile audio system) does not provide an accessible auxiliary signal input, the stimulus sequence must be transferred off-line to the audio system.

This requires fixed timing modes by using static delays between the measurements. The stimulus sequence is generated and exported by the QC system and copied to a suitable medium (e.g. CD or USB stick). The QC system waits for the unique synchronization signal to trigger signal analysis at an arbitrary point of time.

Handheld Recording Device

For measurements with handheld recording devices that

- do not provide a signal output or

- are used for mobile recordings distant from the analyzing system

the measured response shall be analyzed offline. While recording, the microphone signal is stored on the devices storage. The resulting audio file is imported by the QC software for analysis.

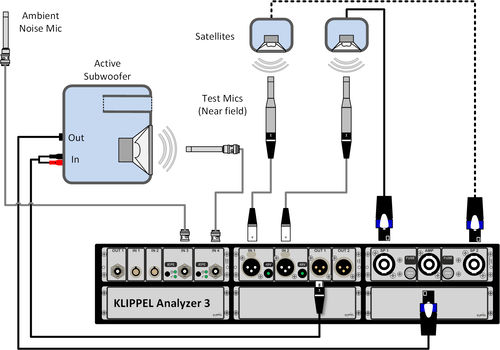

2.1 System

Active systems having internal power amplifiers are connected directly to the XLR outputs. In this example the satellites are passive and hence can also be tested electrically (impedance, T/S and large signal parameters). The total acoustical output is assessed by using a near-field microphone. The second microphone located in the far field detects the ambient noise.

Related Information

Demo Video - Active 2.1 System Testing

AN 64 - Housing Ground Check

Alternate Test Setup

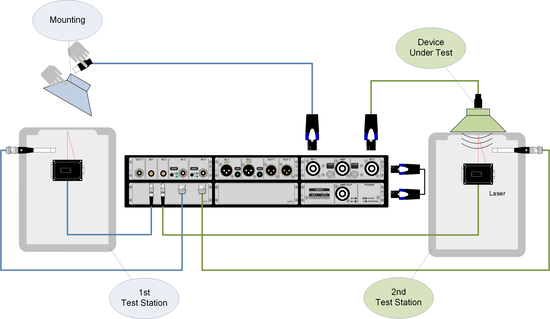

This test setup provides a cost-efficient EoL test solution. Two lines with identical DUTs can be tested by using one KLIPPEL QC System only. One DUT can be mounted / dismounted while the other is tested. Due to the multi-channel capabilities of the KLIPPEL Analyzer, the test environments can be switched automatically (speaker, microphone). An optional ambient noise microphone can be used to ensure Production Noise Immunity.

Adjusting Factory EQ of Active Speakers

Many active audio systems like studio monitors provide a factory equalizer to fine-tune the frequency response and level at the end of the production line. The EQA is a valuable tool to assist the operator in adjusting these controls. In Manual mode, the measurement is repeated until the target response is achieved within specified tolerance. Assisted mode takes it to a more advanced level by giving instructions to optimally adjust the controls within shortest time, even with untrained operators.

Handset Electronics and Acoustic Test

The figure shows an example test scenario for a handset test including electronics and acoustics. The DUT supply voltage is provided by a programmable power supply with GPIB interface controlled by the EXD task. A digital multimeter is used to test DC current and resistance of the handset electronics. The EXD sequence triggers the measurement and checks the results against limits using to generate PASS/FAIL verdicts. This all is combined with acoustical test of the receiver and microphone using the KLIPPEL Analyzer 3 and QC Sound Pressure (SPL) task.

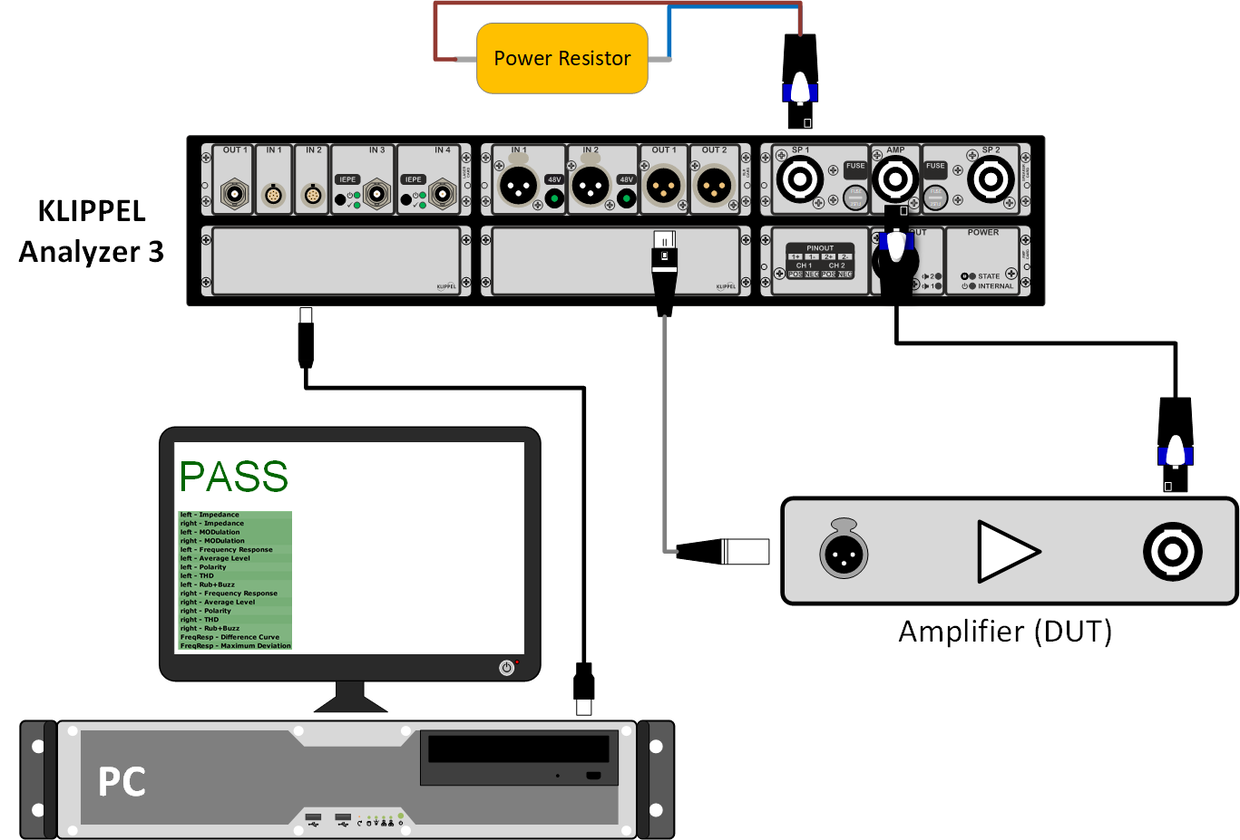

Power Amplifier

In addition to loudspeaker testing, the KLIPPEL Analyzer together with the QC software are highly suitable for quick and automated quality control of audio electronics and power amplifiers in particular.

By looping-in the amplifier (DUT) and connecting a power resistor to the analyzer outputs, both amplifier output voltage and current can be tested under realistic high-power load conditions for two amplifier channels (can be extended by speakON multiplexer). Fundamental frequency response, phase, harmonic and impulsive distortion can be tested within fractions of seconds using a chirp signal while short-term peak power tests can be realized with broad band signals such as multi-tone (MTD), noise or custom wave stimuli (SAN).