Micro Suspension Part Measurement (MSPM)

Features and Benefits

- Specification of suspension parts

- Optimal driver design in R&D

- Defining mechanical limits

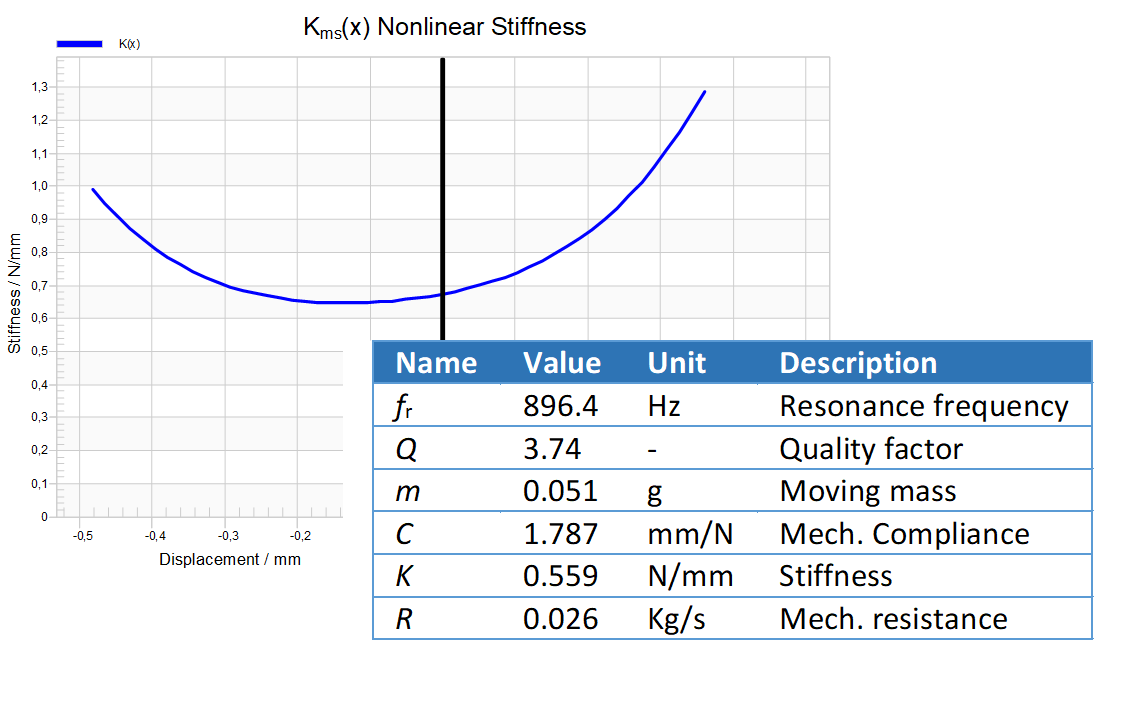

- Measurement of the nonlinear stiffness K(x) of bare membranes without attaching to a loudspeaker

for:- Suspension parts of micro speakers, headphones, tweeters and microphones

- Small membranes (diameter <7cm)

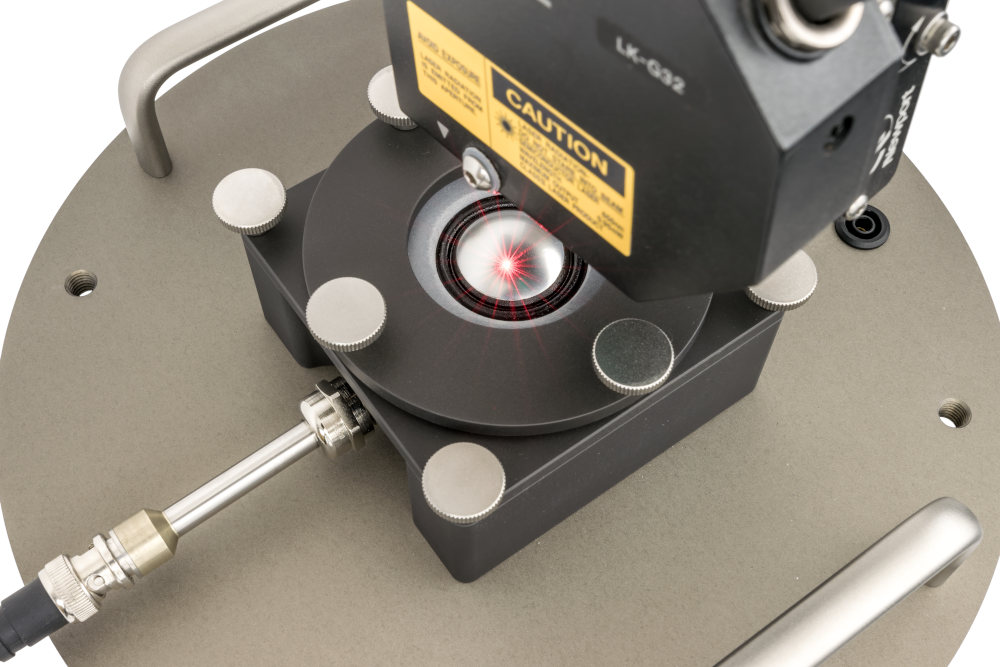

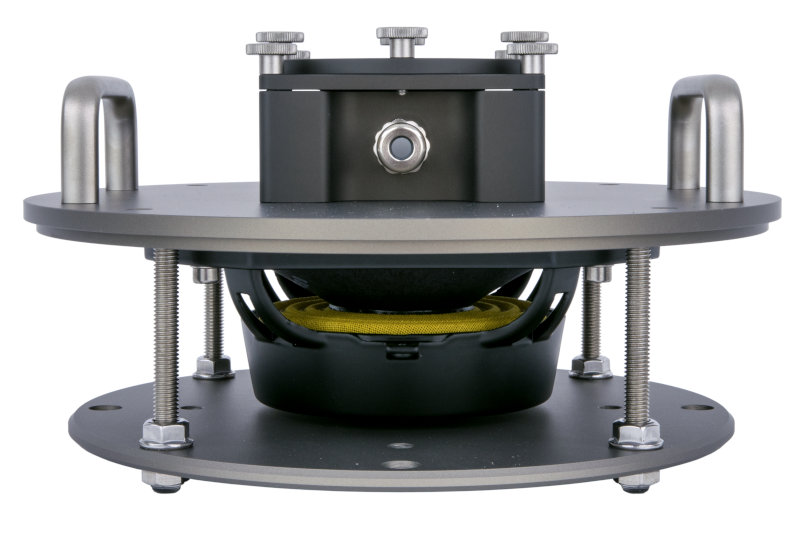

The Micro Suspension Part Measurement (MSPM) is designed for the measurement of the small and large signal parameters of small diaphragms and suspension parts as found in micro speakers, headphones, tweeters or microphones. The part is glued or clamped onto a DUT carrier plate and clamped onto a sealed pressure chamber. The diaphragm is deflected by the sound pressure generated by a sensitive midrange transducer. The linear parameters resonance frequency, Q-factor, stiffness/compliance, moving mass and mechanical resistance are determined dynamically by a simultaneous measurement of displacement and sound pressure.The nonlinear suspension characteristics are additional measured in the large signal domain.

Demo Video (Introduction)

MSPM Pro and MSPM Lite

MSPM Lite

Measurement of resonance frequency & Q-factor and identification of linear parameters

- Stiffness/compliance

- Moving mass

- Mechanical resistance R

MSPM Pro

All features of MSPM Lite

Additional feature: measurement of the nonlinear stiffness K(x) and compliance C(x)

MSPM Bench

The MSPM Bench is a small pressure chamber designed to produce high sound pressures. It is used to pneumatically excite a clamped small diaphragm passively to monitor its vibration behavior. A sealed outlet is provided to measure the sound pressure inside the chamber with a ¼ inch microphone.

Requirements

Hardware

Software

- dB-Lab Software

- MSPM Software

Module

- MPSM Lite: Transfer Function Measurement (TRF)

- MSPM Pro: Linear Parameter Measurement (LPM)

Accessories

- MSPM Bench

- Laser LK-H52

- Microphone

- Power amplifier or KA3 Amplifier Card

- Computer

Laser Positioning:

- LST Bench, Pro Stand or SCN Vibrometer

Related Information

Other Modules of the R&D System

- Suspension Part Measurement (SPM):

For linear and nonlinear testing - Linear Suspension Test (LST)

- Material Parameter Measurement (MPM)

Standards

Patents

Germany: 102007005070; USA: 8,078,433B2; China: ZL200810092055.4; Japan: 5364271; India: 162/DEL/2008