Rub & Buzz and Impulsive Distortion

Characteristics: | KLIPPEL R&D System | KLIPPEL QC System |

|---|---|---|

Peak value of higher-order harmonics (PHD) | TRF-Pro | |

Rms value of higher-order harmonics | TRF-Pro | SPL, SPL-IMP |

Crest-factor of higher-order harmonics | TRF-Pro | SPL, SPL-IMP |

Crest-factor versus voice coil displacement | TRF-Pro | |

Peak value of deterministic component | TRF-Pro | |

Peak value of random component | TRF-Pro | SPL, SPL-IMP, ALD |

Isolated defect distortion | TRF-Pro | MHT |

Noise immunity | ||

| HOHD | TRF-Pro | SPL |

| Hi-2 | DIS | Hi-2 |

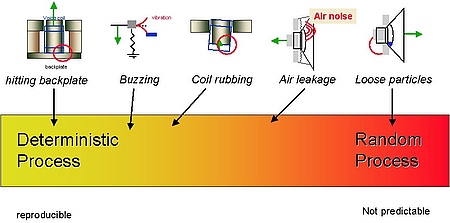

Irregular defects, such as voice coil rubbing in the gap, buzzing parts, loose particles, wire beating, hard limiting of the surround, bottoming of the voice coil former at the back plate, air noise in leaky enclosures, generate impulsive distortion which have not much energy but which generate a wide-band spectrum. Conventional spectral analysis as used for the THD is not a sensitive way for detecting those distortions because the distortion occurs only within a fraction of a period. Time domain analysis and active compensation of the regular motor distortion provide a sensitivity which exceeds human hearing. To use the high sensitivity of the measurement technique in a production environment, the system should also provide some means for detecting ambient noise and for coping with it. Advanced signal processing can exploit unique properties of the irregular defects giving more diagnostic information about the cause of the problem.

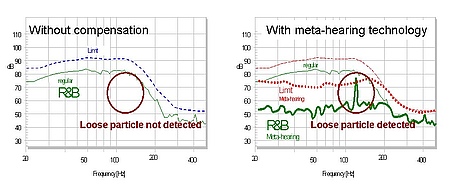

The figure to the left illustrates the masking of the loose particle defect by regular motor and suspension distortion. The right figure shows the Meta-hearing technology of the KLIPPEL QC System where the regular distortion in the R&B measure is compensated and the spike of a loose particle can reliably be detected by a PASS/FAIL limit (red dotted curve) which is below the R&B values without compensation. This active compensation can not be accomplished by a human ear.

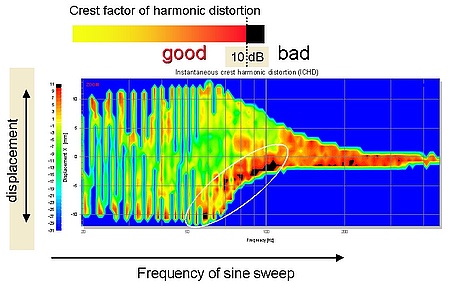

The figure to the left shows the detection of Rub & Buzz and other impulsive distortion within the R&D SYSTEM using the TRF PRO module. For a sinusoidal sweep stimulus (chirp), the instantaneous crest factor of the higher-order harmonics is plotted as a color versus voice coil displacement and instantaneous frequency. For regular distortion the instantaneous crest factor is always low but for impulsive distortion this value exceeds 10 dB, and the crest factor is plotted in black color. The figure reveals impulsive distortion between 60 – 100 Hz at the negative turning point where the peak displacement varies from –10 mm down to 2 mm. This is typical for voice coil rubbing because at those positions the acceleration is maximal and tilts the voice coil former.

KLIPPEL R&D SYSTEM (development)

Module | Comment |

|---|---|

TRF PRO is the perfect tool for detecting any kind of impulsive distortion and for finding the physical cause of the defect. TRF uses the logarithmic sweep stimulus (chirp) to excite the transducer at all frequencies. The higher-order distortion above a user-selected order (usually above 20th order) is separated and analyzed in the time domain. The peak value, rms value and crest factor of the impulsive distortion are plotted versus time or versus instantaneous frequency. An additional 3D plot is very useful to show the instantaneous distortion versus voice coil displacement or sound pressure. This plot reveals the particular instance when the impulsive distortion is generated. |

KLIPPEL QC SYSTEM (end-of-line testing)

Module | Comment |

|---|---|

|

The SPL Tasks provide peak or rms value of the higher-order harmonics above a user-defined order (> 6th order) measured in the time domain which is a sensitive characteristic for Rub & Buzz and for other impulsive distortions. The peak value is recommended to detect loose particles. The task also supports a second microphone located outside the test box in the far field for detecting invalid measurements corrupted by ambient noise. |

Full noise immunity can be realized by using auto-repeat and merging technology. Undisturbed sections of multiple tests are merged to get reliable results although not a single test is free from ambient noise corruption. | |

The regular motor and suspension distortion masks the symptoms of Rub & Buzz at higher amplitude levels. The MHT compensates actively for regular distortion by adaptive modeling and generates the isolated defect distortion. This increases the sensitivity for symptoms of irregular defects, simplifies the limit setting and gives more robustness. | |

The ALD task detects air noise modulated by the air pressure below dust cap or in the test box. The measurement is immune to other noise which is not modulated or modulated with a frequency different than the stimulus. The task also identifies random impulses generated by loose particles and deterministic distortion generated by wire beating, bottoming and buzzing. Measurements corrupted by ambient noise are detected and repeated automatically. | |

| Hi-2 Weighted Harmonic Distortion (Hi-2) | The Hi-2 Feature is based on specially weighted harmonics of 2nd to 10th order. It is mainly used in automotive industry for woofers and subwoofers. |

Example:

Templates of KLIPPEL products

Name of the Template | Application |

|---|---|

TRF rubb+buzz w/o Golden Unit | Rub & Buzz detection without "Golden Unit" according Application Note AN 22 |

TRF rubb+buzz with Golden Unit | Rub & Buzz detection with "Golden Unit" according Application Note AN 23 |

Diagnost. RUB&BUZZ Sp1 | Batch of Rub & Buzz tests with increased voltage (applied to high power devices) |

Diagnost. RUB & BUZZ Sp2 | Batch of Rub & Buzz tests with increased voltage (applied to low power devices) |

TRF Crest Harmonics (x,f) | Crest factor harmonic distortion versus displacement to find Rub & Buzz and other loudspeaker defects |

TRF Peak harmonics, time domain | Peak value of higher-order harmonics in time domain for Rub & Buzz analysis |

Diagnost. MIDRANGE Sp1 | Comprehensive testing of midrange drivers with a resonance 30 Hz < fs < 200 Hz using standard current sensor 1 |

Diagnost. SUBWOOFER (Sp1) | Comprehensive testing of subwoofers with a resonance 10 Hz < fs < 70 Hz using standard current sensor 1 |

Diagnostics MICROSPEAKER Sp2 | Comprehensive testing of microspeakers with a resonance 100 Hz < fs < 2 kHz using sensitive current sensor 2 |

Diagnostics TWEETER (Sp2) | Comprehensive testing of tweeters with a resonance 100 Hz < fs < 2 kHz using sensitive current sensor 2 |

Diagnostics VENTED BOX SP1 | Comprehensive testing of vented box systems using standard current sensor 1 |

Diagnostics WOOFER (Sp1) | Comprehensive testing of subwoofers with a resonance 30 Hz < fs < 200 Hz using standard current sensor 1 |

Diagnostics WOOFER Sp1,2 | Comprehensive testing of subwoofers with a resonance 30 Hz < fs < 200 Hz using current sensor 1 and 2 |

TRF SPL + harmonics | Standard measurement for fundamental component (SPL) and harmonic distortion |

DIS HI-2 | Weighted harmonic distortion (blat distortion) used for Application Note AN 7 |

DIS SPL, Harm protected | Harmonic distortion measurement with protection |

Application Note

Standards

Audio Engineering Society

AES2 Recommended practice Specification of Loudspeaker Components Used in Professional Audio and Sound Reinforcement

International Electrotechnical Commission

IEC 60268-5 Sound System Equipment, Part 5: Loudspeakers

Other Related Tests

Typical Test Objects

Papers and Preprints

W. Klippel, Tutorial “Loudspeaker Nonlinearities - Causes, Parameters, Symptoms,” J. of Audio Eng. Soc. 54, No. 10, pp. 907-939 (2006 Oct.).

W. Klippel, U. Seidel, “Measurement of Impulsive Distortion, Rub and Buzz and other Disturbances,” presented at the 114th Convention of the Audio Eng. Soc., 2003 March 22–25, Amsterdam, The Netherlands, Preprint 5734.

W. Klippel, S. Irrgang, U. Seidel, “Loudspeaker Testing at the Production Line,” presented at the 120th Convention of the Audio Eng. Soc., Paris, France, 2006 May 20-23.

D. Foley, et al., “Higher Order Harmonic Signature Analysis for Loudspeaker Defect Detection,” presented at the 117th Convention of the Audio Eng. Soc., San Francisco, USA, 2004 October 28-31.

P. Brunet, “Enhancements for Loose Particle Detection in Loudspeakers,” presented at the 116th Convention of the Audio Eng. Soc., Berlin, Germany, 2004 May 8-11.

P. Brunet, “Loose Particle Detection in Loudspeakers,” presented at the 115th Convention of the Audio Eng. Soc., New York, USA, 2003 October 10-13.